Accotex aprons stand out for their perfect running behavior, which comes with good friction properties throughout their lifetime. Accotex aprons run vibration-free, offering both highest crack resistance and lowest slippage tendency. Even apron breakages are low, which results in less downtime for the single spindle position.

Aprons

The benchmark – high quality, durability and accuracy- Perfect running behavior

- Highest product reliability

- Outstanding lifetime

What to expect

Standard

All these features combined result in fewer machine standstills or interruptions, which guarantee highest machine efficiency.

Area of application

Accotex aprons stand for trouble-free processing of all common fibers under various climate conditions.

Manufacturing standards

The most advanced compound technology combined with high-tech chemistry, select high-quality raw materials, and a state-of-the-art production facility with the latest mixing technology lead to highest product reliability.

Product promise

Precise product dimensions and highest dimensional stability are hallmarks of Accotex aprons. The stable and consistent production of the aprons is the key to superior life cycles for all common fibers. The aprons offer sufficient resistance to all popular fiber finishings and colors.

Types, sizes and surfaces

The aprons are available in a wide range of dimensions. Standard sizes can be delivered with a knurled inside structure.

Short-staple spinning

Accotex aprons for short-staple spinning applications offer a long service life and excellent spinning characteristics.

They stand out for reliability, close tolerances, low friction and high abrasion resistance. Accotex aprons for short-staple spinning applications provide stable and excellent results on each spinning position.

Ring spinning aprons

| PRODUCT | APPLICATION | FiBER | Outer layer | Inner layer |

|---|---|---|---|---|

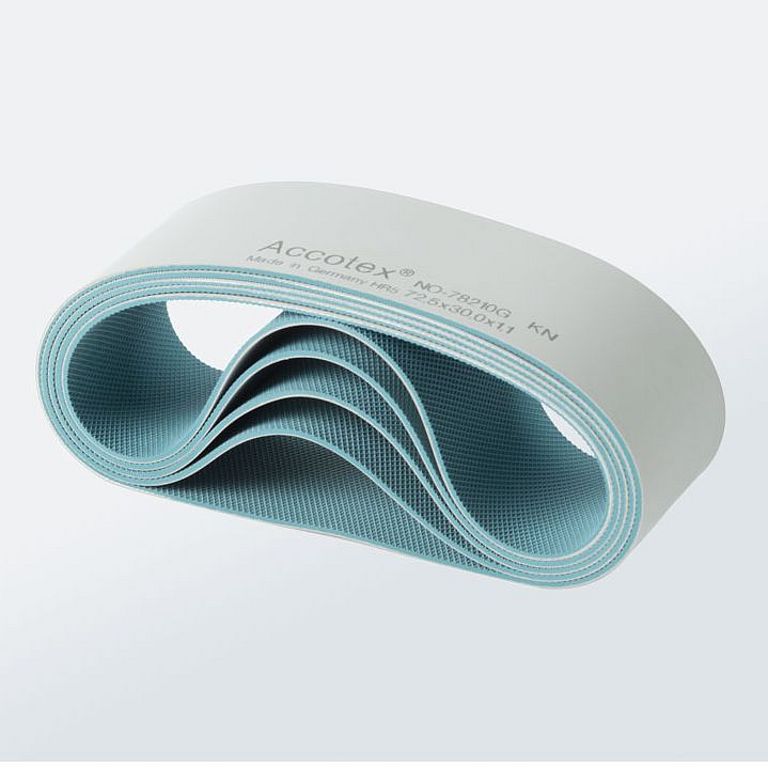

| NO-78210G | Top and bottom* apron | All | Gray | Green |

| NO-78210GX | Top and bottom* apron | All | Gray | Gray |

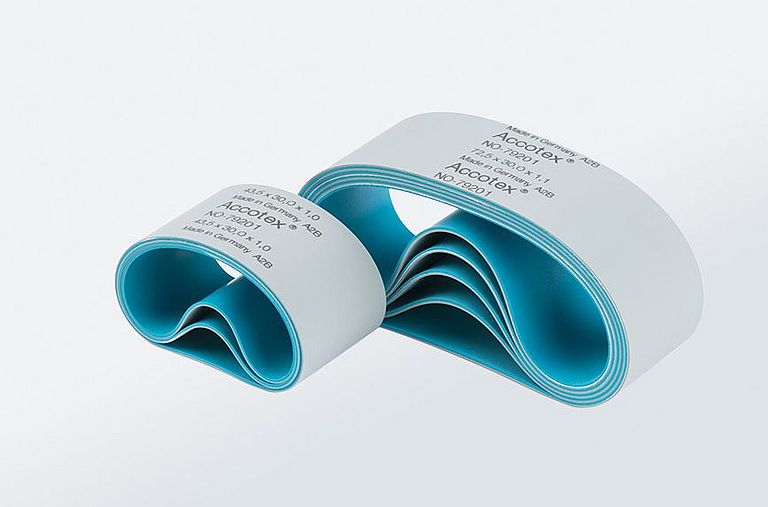

| NO-79201 | Top and bottom* apron | All | Gray | Blue |

| NO-78210G knurled** | Bottom* apron | All | Gray | Green |

| No-79201 knurled** | Bottom* apron | All | Gray | Blue |

* All bottoms aprons available as skived/preglued version

** Knurled version available with 72.5 / 76.3 / 79.0 mm inner diameter

Long-staple spinning

Accotex aprons for long-staple spinning applications offer a long service life and excellent outstanding spinning characteristics.

Accotex aprons for long-staple spinning applications stand out for low friction, close tolerances, and high abrasion resistance. The high-quality rubber compounds that are used also offer high chemical resistance to common fiber finishes and colors. The aprons are known for stable and excellent properties from spinning position to spinning position.

Ring spinning aprons

| PRODUCT | APPLICATION | FiBER | Outer layer | Inner layer |

|---|---|---|---|---|

| NO-78210GX | Top and bottom* apron | All | Gray | Gray |

| NO-79201 | Top and bottom* apron | All | Gray | Blue |

* All bottoms aprons available as skived/preglued version

The flexible Apron

The Accotex apron NO-79201 is made from new compounds that deliver longer life and better performance. Flexible enough to work with all fiber types across ring and compact-spinning machines. All in all the newly developed Accotex NO-79201 is a flexible usable spinning apron of the latest generation features a number of striking and prominent characteristics:

- Excellent fiber grip and fiber guidance

- Highly improved inner layer crack resistance

- Superior friction properties over the whole service life

- Very good swelling resistance and smooth and trouble-free running

- High material flexibility with at once outstanding mechanical robustness

The NO-79201 can be supplied with a plain inside or a specially configured inner layer pattern, known as a knurled version.

The main benefit is to provide less contact area to the nose bar, which enables lower torque, and thus less stress on the bottom roller bearings. This also allows the inside structured apron to run clean on so-called "dirty" fibers and to work efficiently in demanding environmental conditions in terms of fiber cleanliness.

The knurled apron version is available with inner diameters of 72.5, 76.3 and 79.0 mm.

In addition, the NO-79201 range is available as closed apron, skived bottom apron and skived and pre-glued bottom apron.

Contact

Find the sales and service contacts for your country here.