The air-jet spinning technology is characterized by high process speeds combined with high fiber throughputs. Accotex offers the ideal aprons for this with maximum durability and stability. Very close tolerances and high design precision define the quality of these aprons. They contribute to the ongoing success of the air-jet spinning technology.

Aprons

Leading parts for revolutionary spinning technologies- Perfect running behavior

- Highest product reliability

- Outstanding lifetime

What to expect

Standard

All these features combined result in fewer machine standstills or interruptions, which guarantee highest machine efficiency.

Area of application

Accotex aprons stand for trouble-free processing of all common fibers under various climate conditions.

Manufacturing standards

The most advanced compound technology combined with high-tech chemistry, select high-quality raw materials, and a state-of-the-art production facility with the latest mixing technology lead to highest product reliability.

Product promise

Precise product dimensions and highest dimensional stability are hallmarks of Accotex aprons. The stable and consistent production of the aprons is the key to superior life cycles for all common fibers. The aprons offer sufficient resistance to all popular fiber finishings and colors.

Types, sizes and surfaces

The aprons are available in a wide range of dimensions. Standard sizes can be delivered with a knurled inside structure.

Air-jet spinning aprons

| PRODUCT | APPLICATION | Size | FiBER | Outer layer | Inner layer |

|---|---|---|---|---|---|

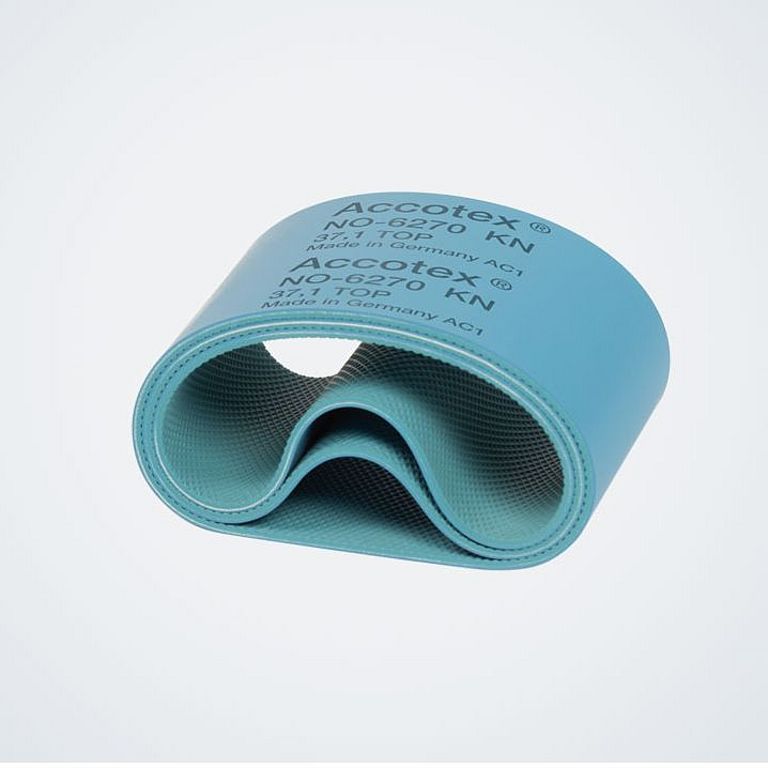

| NO-6270 KN | Top apron | 37.1 x 32.0 x 1.0 mm | CO Blends MMF | Blue | Green |

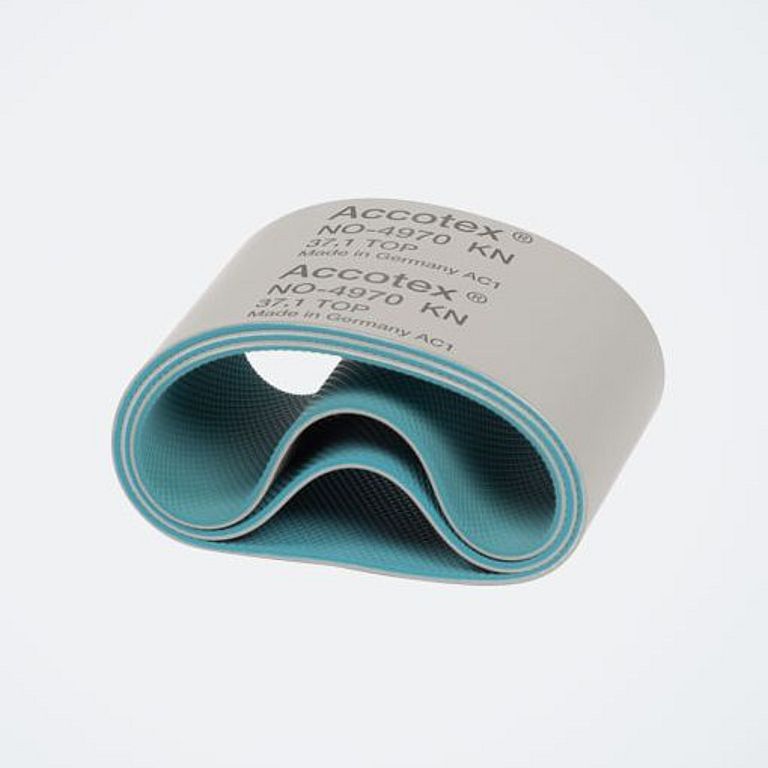

| NO-4970 KN | Top apron | 37.1 x 32.0 x 1.0 mm | CO Blends | Gray | Green |

| NO-4970 KN | Bottom apron | 38.2 x 34.0 x 1.0 mm | CO Blends | Gray | Green |

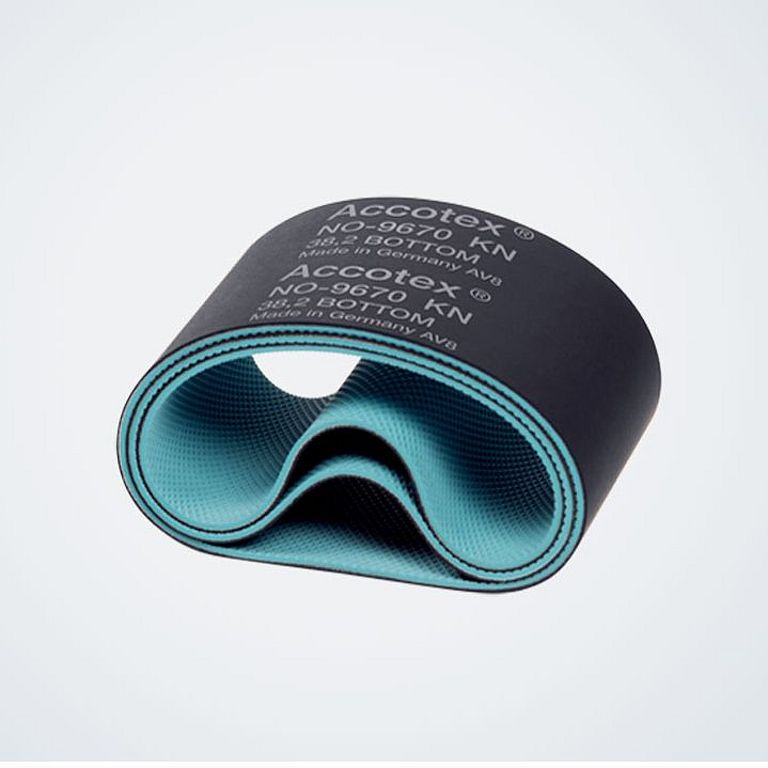

| NO-9670 KN | Bottom apron | 38.2 x 34.0 x 1.0 mm | MMF Blends | Black | Green |

Cotton (CO), Man-Made Fibers (MMF)

Contact

Find the sales and service contacts for your country here.